One of the main reasons why engraving machines malfunction (or perform poorly) is neglect. Most people take their machines in for repairs when a problem has already shown itself while many still believe that such issues tend to sort themselves out.

With proper maintenance, you significantly prolong the lifespan of your engraving machine, but you will also cut the costs of repairs considerably. If you don’t know what you should and should not be doing with your laser cutting machine in terms of maintenance, I’ve got you covered.

After reading this article, you will have learned how to properly maintain your engraving machine.

Daily Maintenance

Daily maintenance of an engraving machine is arguably more important than weekly and monthly maintenance; by performing it, you ensure that the machine can operate smoothly, and more importantly, you are contributing to lowering the risks of accidents happening in the workplace (even if it is your garage).

Dos

The main tasks on your daily maintenance checklist revolve around checking the hardware, gas supply, and inspecting the machine for dents, cracks, or leaks. Start off by checking the cooling element (typically it’s water in a freezer-type box).

After that, check if the machine has sufficient gas supply. This could be tricky, as you’re basically inspecting the pressure, not the amount of gas that is left. Depending on the machine model, the interface may show PSI (pounds-per-square-inch) or simply light up if the gas container needs to be replaced.

Modern machines usually feature a gauge that shows the remaining supply of water, gas, and other resources while some older models have indicator lights that will turn on when the supply is low.

Don’ts

The first rule of engraving machine maintenance is to never leave the machine unattended while it is operational. Many people disregard the fact that engraving machines are incredibly powerful and could cut through a sturdy piece of furniture and set the place ablaze in moments.

Another thing that you want to ensure never takes place is to have heaps of waste lying around the working area. By waste, I mean leftover plastic or metal from the engraving/cutting process, as well as plastic bags, containers, cellophane, or anything overly flammable.

Finally, always stick to the prescribed shutdown procedure. It’s different for each model, and no matter how small the differences may be, it’s imperative to not skip a step just because you’re in a hurry.

Weekly Maintenance

Weekly maintenance is based on cleaning the accumulated debris in air outlets and gas filters, refilling the lubricant (or lubing the axes if a lube compartment isn’t available), and essentially tending to the parts that are expected to degrade over time.

Dos

The basics of monthly maintenance require a simple toothbrush and the simplest tools. One of the first things on your list should be checking for loose screws and bolts; tighten them if they’re functioning properly. If not, buy and install replacements as soon as possible.

A single missing screw usually won’t have such a tremendous impact on how safe the machine is, but it’s better to not risk it.

Whenever you are using your engraving machine, it will inevitably create tiny particles of debris that will pile up in the work area. Additionally, debris will begin building up in air outlets due to ventilation, so to ensure the air filters are working properly, remove debris from here on a weekly basis.

You should also inspect the surroundings of the control cabinet, as they are typically supplied with ventilators as well. Keep the area clean of debris by cleaning it at least once in two weeks.

Don’ts

One of the things that you shouldn’t leave to chance is the lubrication of the axes. It’s normal for inexperienced engraving machine operators to believe that the machine is slower than usual because it’s old. More often than not, the axes have started to rust.

By lubing the axes on a weekly basis, they will continue functioning as normal for years, if not decades. Certain engraving machine models feature special lube compartments; feed the lubricant to the designated spot, and the process will automatically commence at the push of a button.

Don’t neglect the focusing lens. It’s one of the most critical parts of the engraving machine and you’ll need to check whether it’s still in place and intact at least once every two weeks.

Its surface shouldn’t be touched directly nor with water or damp cloth. Use a thin, soft, and dry piece of cloth to clean the lens, or the coating may become damaged.

Irregular Maintenance

Monthly, half-year and yearly engraving machine maintenance can be unified and called “irregular” maintenance. It’s typically performed when critical parts are severely damaged, or if there is anything wrong with the engraver (laser).

Dos

After a while, impurities may contaminate the water in the cooling element, but bits of debris may contaminate the oil in the tanks as well. This specifically applies to oil in the roots and vacuum pumps. It is recommended to change water and oil at least once a month, if not sooner.

While you are refilling water and oil, you’ll have a perfect opportunity to check for leaks. If there’s even one tiny hole, replace the container and don’t use the machine before the new one is installed.

Dont’s

Cleaning the laser engraver head is a difficult process that you don’t want to neglect. Not only is its cavity hard to reach, but there are many delicate parts that could easily get damaged by accident. Don’t do it yourself if you are not experienced enough yet.

Final Thoughts

Engraving machines are quite demanding when it comes to maintenance, but it’s a necessary process that should not be avoided nevertheless.

Let me give you one final piece of advice. You may feel that delegating machine maintenance to the experts is easier, but you’ll throw hundreds of dollars down the drain this way.

Furthermore, knowing how to clean and perform basic repairs can save your machine (and your workspace); there may be situations when you won’t have enough time to call for repairs.

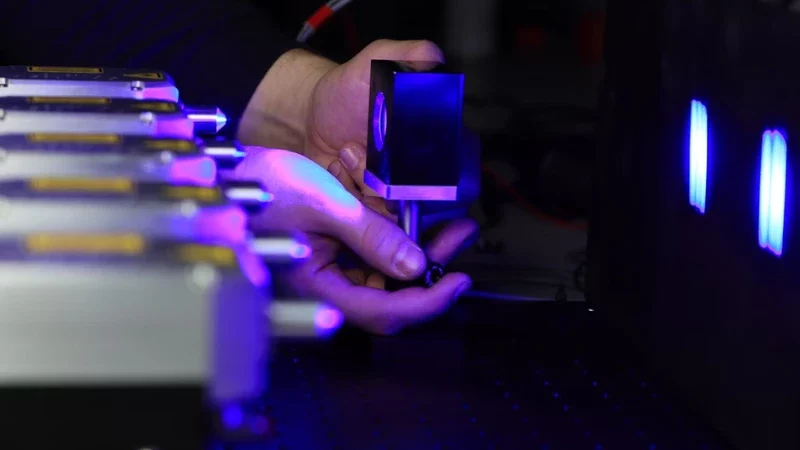

Photo Credit: Unsplash